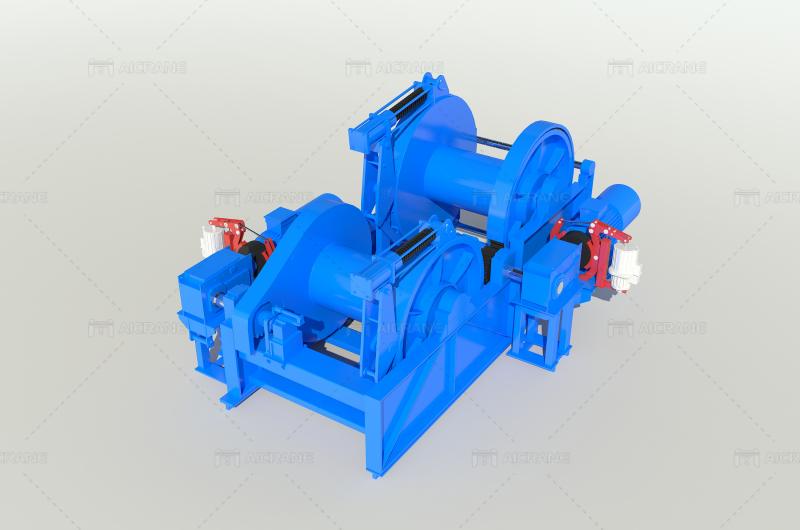

The 50 ton winch stands as a stalwart of heavy lifting capabilities in both construction and offshore industries, providing essential support for a range of tasks that require robust lifting power. This article delves into the innovative uses of 50 ton winches in these sectors, exploring their applications, benefits, and contributions to efficiency and safety.

Applications in Construction Industry

Structural Erection: In construction projects, 50 ton winches are indispensable for erecting structural elements such as steel beams, columns, and prefabricated modules. Their high lifting capacity allows for the precise positioning of heavy materials at various heights, ensuring structural integrity and safety during assembly.

Material Handling: These winches efficiently handle large construction materials like concrete panels, roofing materials, and equipment. They facilitate quick and safe transportation across construction sites, minimizing manual handling and accelerating project timelines.

Foundation Work: During foundation construction, 50 ton winches are utilized to install piles, drill rigs, and other equipment. Their powerful pulling force enables the efficient placement of foundation components, contributing to the stability and durability of structures.

Demolition Operations: In demolition projects, 50 ton winches aid in the controlled dismantling of buildings and structures. They assist in lowering heavy debris safely to the ground, reducing the risk of accidents and ensuring a systematic approach to site clearance.

Applications in Offshore Industries

Offshore Platform Maintenance: Offshore platforms require regular maintenance and repair to ensure operational efficiency and safety. 50 ton winches play a critical role in lifting heavy equipment and replacement parts onto platforms, facilitating timely repairs and minimizing downtime.

Anchor Handling: In the offshore oil and gas sector, 50 ton winches are employed for anchor handling operations on vessels and floating platforms. They secure and maneuver heavy anchors with precision, ensuring the stability and positioning of marine assets in varying sea conditions.

Subsea Equipment Deployment: The subsea environment presents unique challenges for equipment deployment and retrieval. 50 ton marine winches are utilized to lower and retrieve subsea equipment such as remotely operated vehicles (ROVs), sensors, and pipelines. Their robust design and precise control capabilities are essential for conducting operations at significant depths.

Emergency Response: During emergency situations offshore, such as equipment failures or rescue operations, 50 ton winches provide critical lifting support. They assist in evacuating personnel, transporting emergency supplies, and conducting salvage operations with efficiency and safety.

Benefits and Advantages

High Lifting Capacity: The primary advantage of 50 ton winches is their substantial lifting capacity, which allows them to handle heavy loads effectively. This capability is essential in both construction and offshore environments where large and bulky items need to be lifted and maneuvered.

Precision and Control: Modern 50 ton winches are equipped with advanced hydraulic or electric systems that provide precise control over lifting and lowering operations. This precision ensures accurate positioning of loads, enhances safety, and reduces the risk of damage to materials and equipment.

Safety Features: Safety is paramount in construction and offshore operations. 50 ton winches are equipped with safety features such as overload protection, emergency stop mechanisms, and fail-safe brakes. These features mitigate risks and ensure secure handling of heavy loads in challenging environments.

Versatility: Despite their high lifting capacity, 50 ton winch equipment are versatile tools that can be adapted for various tasks. They support a wide range of applications in construction, offshore drilling, marine operations, and emergency response, making them invaluable assets in diverse industries.

Case Studies and Examples

Construction Project Example: In the construction of high-rise buildings, a 50-ton winch was used to lift and position prefabricated concrete panels efficiently. This method accelerated the construction schedule and reduced labor costs while maintaining strict safety standards.

Offshore Platform Maintenance: A case study in the offshore industry demonstrated how a 50-ton winch facilitated the replacement of a critical pump on an offshore platform. The winch’s lifting capacity and precise control enabled the safe and swift installation of the new equipment, minimizing downtime.

Future Trends and Innovations

Automation and Remote Operation: Future advancements in 50-ton winch technology may include automation and remote operation capabilities. These features would allow operators to control winch operations from a safe distance, improving efficiency and safety in hazardous environments.

Integration with IoT and Monitoring Systems: Smart sensors and Internet of Things (IoT) integration could provide real-time data on winch performance, load conditions, and maintenance needs. This data-driven approach would optimize operational efficiency and facilitate predictive maintenance practices.

The innovative uses of 50-ton winches in construction and offshore industries highlight their pivotal role in enhancing productivity, safety, and operational efficiency. From lifting heavy construction materials to supporting critical offshore operations, these versatile tools continue to evolve with technological advancements. Investing in 50-ton winches is a strategic decision for industries seeking to optimize their lifting capabilities and achieve superior project outcomes in challenging environments. Want to get further information about different products? Just check this website for your reference: https://aicranemachine.com/.