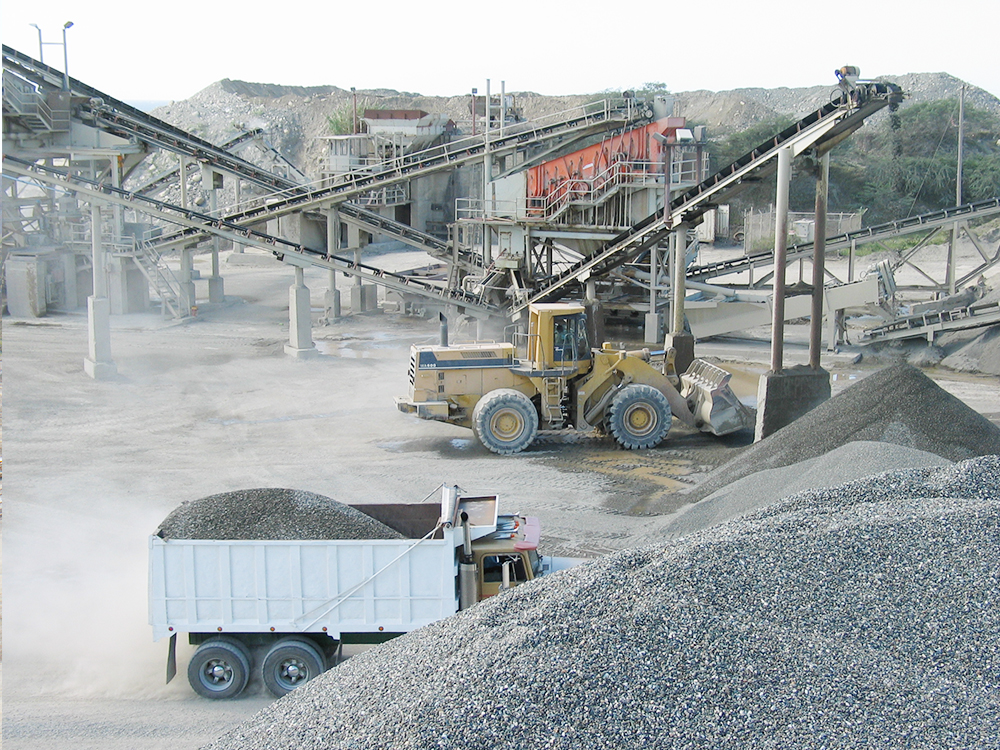

If you have ever looked at a facility that had a crusher plant, you know that they are quite elaborate. They are designed to work efficiently, breaking down minerals, sometimes in a matter of minutes. There is a feed bin where the materials will be placed which starts the process, and at the end of the process, the material will be deposited via conveyor belts to where they need to go. Here is a brief overview of how you can layout a crusher plant layout if you are planning to do this on your own.

Flow Process Of A Crusher Plant

The process of breaking down rocks may seem to be a very simple set of procedures. In reality, it can become quite complex. That’s because there are diverse problems that can occur as you are breaking down these different minerals. They often go through a minimum of three or four processes until you get the final product. It begins with the area where the rocks are initially put into a feeder. This leads to the initial crusher which is typically a jaw crusher. It has a wide opening, a stationary plate, and one that can move back and forth. The smaller components that break off are going to be funneled to the bottom.

The Next Stage

From there, this material will be sent by conveyor belts to another crusher. Typically an impact crusher that can break it down even further. This is typically a cone crusher device. It performs what is called secondary crushing. It is able to take minerals that are broken down, which may begin at over a thousand millimeters, all the way down to 35 mm in certain cases. From there, this will also drop down onto a conveyor belt to go to the tertiary stage of this process.

The Final Stage

In this final stage, you will have a vibrating screen that may be used to get rid of unwanted materials. This could happen in between each of the sessions where the minerals are crushed. This will also require some type of section system to eliminate the dust particulates that can be problematic if they are breathed in. The third stage, sometimes called the final stage, uses a type of impact crusher that can break it down even further. These materials will be far smaller than 35 mm, and can even be further processed into a form of dust.

Storage Of The Materials

The final step of the process is the storage of the materials that are produced. These are going to be in a bin or even just in piles. If you are working with a very fine aggregate material, you may have containers or silos where they are placed. This will be the sand that is often used in the mixture of concrete. It can be of different diameters, creating either coarse or very fine sands. This entire process can take quite a bit of time, and as you are rotating different types of rocks and minerals, you also need to prep the entire system to start over again.

This is the most common crushing plant layout that is often used. You can have deviations of this if you want. The difficulty is having enough room for all of the different machines. There is also quite an investment if you are just starting out. It is important to have a sizable quarry where you can get access to different types of rocks and minerals that are at that location. Finally, there are the areas where you will have the ability to provide storage for all of these materials that can be used by your company or can be obtained by local businesses that want to use these products.